Story of the Month: TX-10000 Project Completion

A Mammoth Undertaking Successfully Completed at Gulf Copper

The Gulf of Mexico’s vibrant energy sector relies on innovation; sometimes, that innovation comes in sheer scale. This week, Gulf Copper celebrated the successful completion of a remarkable project: the inspection and preparation of the TX-10000, a one-of-a-kind salvage vessel and the largest in the United States. This mammoth undertaking, a testament to Gulf Copper’s expertise in handling complex marine projects, marks a significant milestone for our company and the industry.

Since the TX-10000 arrived at our Galveston yard in January, our team has worked tirelessly alongside Xenos Marine and their partners. The scale of this vessel presented unique challenges, demanding meticulous planning, precise execution, and unwavering dedication. Every aspect of the project, from initial inspections to final preparations, required a collaborative effort and a commitment to excellence, which defines Gulf Copper’s approach.

Honoring Our Maritime Heritage on National Maritime Day

Today, on National Maritime Day, Gulf Copper joins the nation in celebrating the vital role of the maritime industry in shaping our world. For over 76 years, we’ve been proud to be a part of this incredible legacy, providing essential repair and maintenance services to the vessels that power global commerce and bolster national security.

The maritime industry’s impact resonates far beyond our shores, connecting communities across the globe and driving economic prosperity. From the Gulf of Alaska to ports worldwide, countless vessels traverse the seas, carrying goods, supporting trade, and safeguarding our interests. At Gulf Copper, we understand the significance of this interconnected network and the dedication it requires.

We take immense pride in our skilled workforce, whose expertise and commitment are the foundation of our success. Their tireless efforts ensure that vessels remain operational, efficient, and safe, contributing to the seamless flow of goods and the strength of our nation’s maritime infrastructure. On this special day, we salute our hardworking staff across the United States and Mexico, recognizing their invaluable contributions to the maritime industry. Without their dedication, none of this would be possible.

We extend our sincere gratitude to all of our nation’s maritime workers. Your hard work, skill, and unwavering commitment keep our economy moving and our nation strong.

Happy National Maritime Day!

Story of the Month: The TX-10000 Project

Innovating Maritime Solutions: The TX-10000 Project

We at Gulf Copper and Manufacturing and Gulf Copper Energy Services (GCES) are excited to share some thrilling news regarding our ongoing support for the TX-10000, the largest heavy-lift vessel in the United States. Our team has been diligently working to ensure that this remarkable vessel operates at peak performance, and we are proud to announce that we will be undertaking essential maintenance during its upcoming stay at our facility on the 35,000-t dry dock in Galveston.

This maintenance will include critical tasks such as repainting and thruster servicing, vital for the TX-10000’s operational efficiency. Our dedicated GCES team has provided rigging, lifting, inspections, and HSE support for several years, ensuring that the vessel remains in top condition while out in the field. Our shipyard team will now dry dock the vessel.

Story of the Month: Independencia II Mooring

Reinforcing Independence:

OOS-Enabled Independencia II Mooring System Upgrade

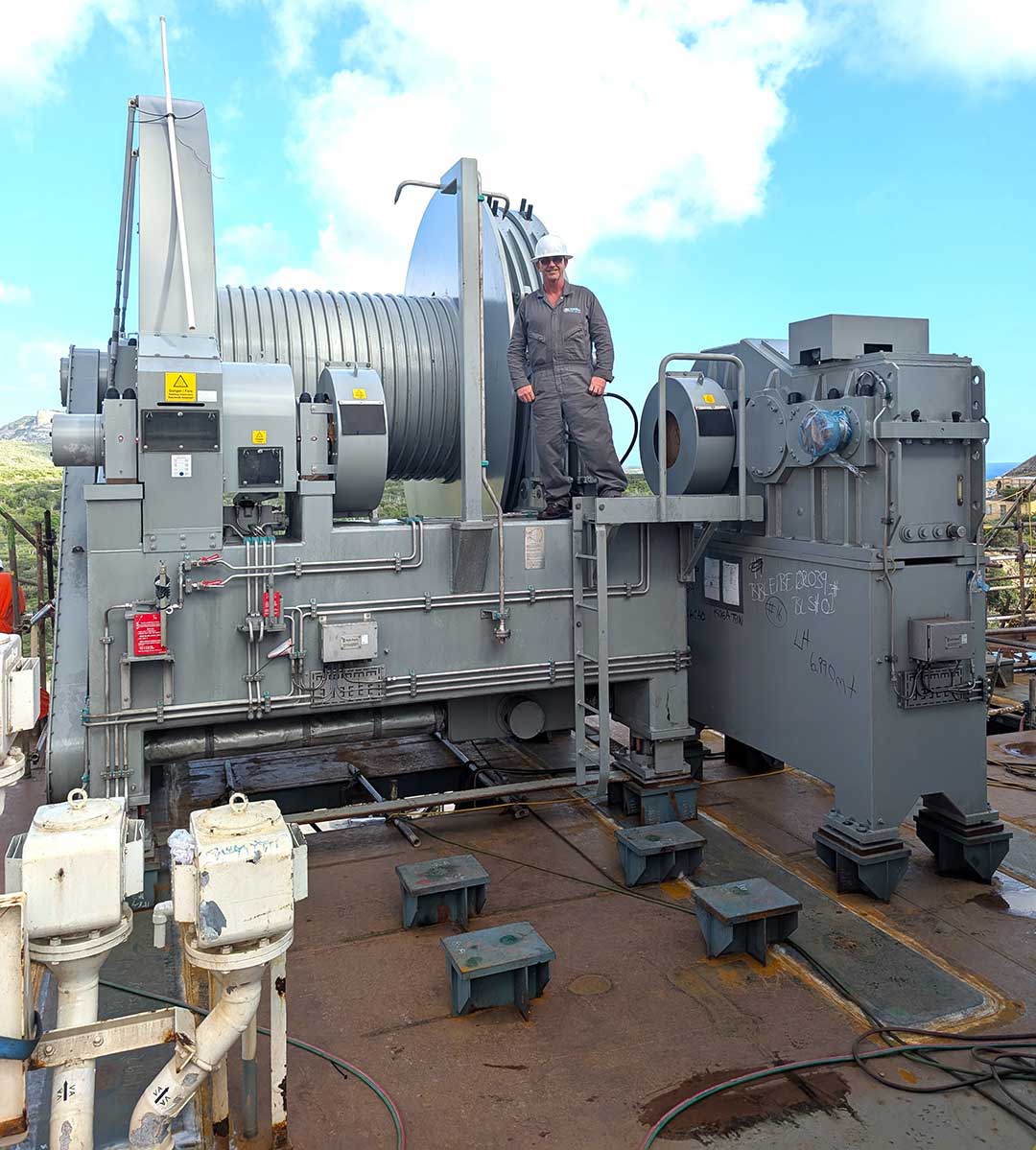

The maritime industry demands constant innovation, pushing the boundaries of logistics to achieve ambitious goals. We thrive on these challenges at Gulf Copper Energy Services (GCES). Our recent work on the OOS-enabled Independencia II, a semi-submersible offshore drilling rig operating in demanding offshore environments, exemplifies our commitment to delivering complex projects with precision and efficiency. This wasn’t just maintenance but a transformation, bolstering the vessel’s capabilities and extending its operational lifespan.

The project centered around a significant upgrade to the vessel’s mooring system foundation. This involved enhancing the vessel’s structural integrity to accommodate two fairleads on each column and two winches on each deck’s four corners—a crucial upgrade for increased stability and operational flexibility in challenging offshore conditions. The scale of this undertaking was substantial, requiring the installation of 160 tons of prefabricated steel, meticulously distributed with 40 tons allocated to each column.

Our scope extended beyond mere installation. It encompassed a comprehensive approach, from the initial fabrication and assembly of components at our Galveston yard to the final installation and alignment of critical machinery onboard the vessel. This included precise winch gearbox and motor alignment, ensuring optimal performance and longevity, and fitting operator cabins for enhanced crew comfort and operational control.

The project commenced in early September 2024 and is expected to conclude in mid-March 2025. The fabrication phase alone, conducted at our state-of-the-art Galveston facility, demanded approximately 20,000 man-hours of skilled labor. Our team meticulously cut, prepped, and welded steel components into precise installation pieces, adhering to the highest quality and safety standards.

The logistical complexities of this project were considerable. Transporting the fabricated steel, specialized tools, and essential equipment required a carefully orchestrated multi-modal approach. 162 pallets were dispatched via 31 truck shipments from our GCES facility to the shipping company in Fort Lauderdale, Florida, with departures staggered between September 21, 2024, and January 13, 2025. From there, 13 separate sea freight shipments conveyed the cargo to Curacao, where the Independencia II was located.

Independencia II SF Winch

On board the vessel, a dedicated team of 65 skilled professionals worked tirelessly to execute the installation. Led by Shaun Flower (Project Manager) and Emilio Guzman (Project Supervisor), the team included seven additional supervisors overseeing a highly trained workforce of welders and fitters sourced from our Mexico office. This collaborative effort resulted in approximately 70,000 onboard man-hours, encompassing the core installation and additional tasks crucial to the vessel’s operational readiness.

The success of this project is not just measured in tons of steel or man-hours but also in the positive feedback received from our client. Christopher Stephen Hawkins, Project Planner/Document Controller for OOS, commended our team’s professionalism and near-perfect safety record. He specifically highlighted the strong leadership of Shaun and Emilio, recommending them for advancement, and praised the dedication and skill of the entire welding and fitting crews. Further feedback from OOS Project Manager Eddie Sarkis acknowledged the excellent quality of work, strong supervision, and the team’s adaptability in performing tasks beyond their assigned trades. He noted their willingness to assist with winch alignment and responsiveness to changing project requirements.

The Independencia II project underscores GCES’s capabilities in delivering complex, large-scale marine solutions. We are proud of our team’s dedication, expertise, and commitment to safety and quality, and we look forward to continuing to provide innovative solutions for the maritime energy sector.

Scenic Eclipse Back in Action

Scenic Eclipse Back in Action Thanks to Gulf Copper’s Swift Drydock Expertise

The luxury expedition ship Scenic Eclipse has returned to service following critical repairs conducted at Gulf Copper’s Galveston shipyard. The vessel, known for its adventurous itineraries, experienced propulsion issues in September, necessitating an urgent drydock to replace a faulty Azipod.

Gulf Copper’s team swiftly responded to the challenge, accommodating the 228-guest ship and facilitating the complex repair process. Remarkably, the replacement Azipod was delivered to the shipyard via a chartered Antonov 124 aircraft, one of the world’s largest cargo planes, highlighting the scale and urgency of the operation.

GC Sets Sail for the International WorkBoat Show 2024!

The Future; Underway

New Orleans, LA – Nov 12-14, 2024

The maritime world is gearing up for the biggest event of the year—the International WorkBoat Show 2024! From November 12-14, New Orleans will be buzzing with the latest innovations and industry insights. And Gulf Copper will be right in the heart of it all.

This year’s WorkBoat Show promises to be bigger and better than ever, with a focus on “The Future; Underway.” Attendees can expect:

- Cutting-edge technology: Explore the newest advancements in vessel design, propulsion systems, and subsea solutions.

- Expert insights: Learn from industry leaders at the WorkBoat Conference Program.

- Networking opportunities: Connect with thousands of professionals, from vessel owners and operators to vendors and suppliers.

- Exciting events: Don’t miss the State of the Jones Act Breakfast, the Significant Boats Awards, and much more!

Visit Gulf Copper at Booth #1854

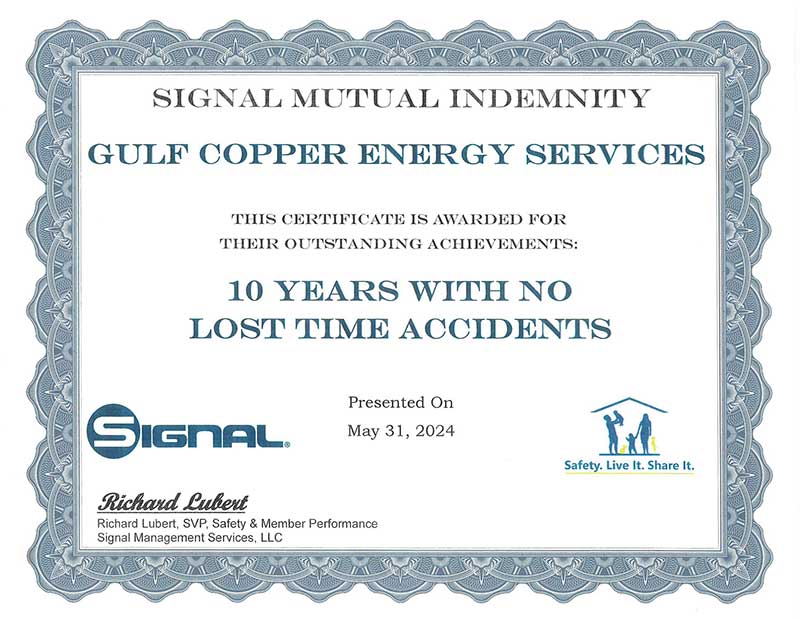

Story of the Month: GCES Celebrates a Decade of Safety Excellence

Gulf Copper Energy Services (GCES) recently received a prestigious merit certificate from Signal Management Services, marking an impressive milestone: ten years without a Lost-Time Incident (LTI). This achievement underscores GCES’s unwavering commitment to safety in the offshore and marine shipping industries’ challenging and often high-risk environments.

Gulf Copper Energy Services (GCES) recently received a prestigious merit certificate from Signal Management Services, marking an impressive milestone: ten years without a Lost-Time Incident (LTI). This achievement underscores GCES’s unwavering commitment to safety in the offshore and marine shipping industries’ challenging and often high-risk environments.

Senior GCES management proudly accepted the award on behalf of the dedicated employees whose daily vigilance and commitment to safe practices made this milestone possible. This accomplishment is not merely a statistic; it represents countless hours of training, meticulous planning, and a shared culture of prioritizing safety.

GCES recognizes that safety is an ongoing journey. While celebrating this remarkable accomplishment, the company reaffirms its commitment to continuous improvement. It constantly seeks opportunities to enhance its safety protocols and empower employees to work in the safest possible conditions. This dedication protects the workforce, fosters operational efficiency, and strengthens GCES’s reputation as a reliable and responsible partner in the energy sector.

Congratulations to Gulf Copper Energy Services on this outstanding achievement!

Story of the Month: GCES Rope Teams Rise to the Challenge

Gulf Copper Energy Services Rope Teams Rise to the Challenge at Dali/Baltimore Bridge Incident

When disaster strikes, Gulf Copper Energy Services (GCES) is ready to respond. This month, our highly skilled rope access team demonstrated their expertise and dedication in a critical situation involving the Dali/Baltimore Bridge. When a vessel collided with the bridge, causing significant damage and threatening the integrity of the structure, GCES was called upon to provide essential rigging support for the removal of unstable cargo containers.

Our rope team, renowned for their experience in challenging environments, worked tirelessly alongside other emergency responders to secure the area and develop a safe removal plan. Using specialized rigging techniques and their in-depth knowledge of rope access systems, our team safely removed the containers, preventing further damage to the bridge and ensuring the safety of everyone involved. This swift and effective response is a testament to the professionalism and dedication of our GCES rope access team, highlighting Gulf Copper’s commitment to providing exceptional services in even the most demanding situations.

Gulf Copper Proudly Supports Battleship Texas’ Historic Restoration

At Gulf Copper, we’ve always been honored to play a role in preserving history. That’s why we’re thrilled to be a part of the ongoing restoration of the Battleship Texas, a legendary World War II vessel that bravely fired the first shots on D-Day. This iconic ship, a symbol of American courage and resilience, served our country with distinction, participating in numerous battles and earning 11 battle stars.

The Battleship Texas Foundation, a dedicated non-profit organization, has embarked on an ambitious $35 million restoration project to ensure this historic ship can continue inspiring future generations. Gulf Copper is proud to be a partner in this effort, contributing our expertise and world-class facilities at the Gulf Copper Dry Dock & Rig Repair in Galveston, Texas.

The extensive restoration efforts, which have been underway since 2022, have already seen over 700 tons of steel replaced and the hull repainted. With the ship successfully refloated in March 2024, the focus is shifting towards restoring the interior spaces, replacing the wood deck, and finalizing the navigation bridge.

We firmly believe that the Battleship Texas is a national treasure that deserves to be preserved. It’s a tangible reminder of the sacrifices made by those who fought for our freedom.

Learn more about the Battleship Texas’ incredible journey and this historic restoration project:

KXAN News: Inside Battleship Texas’ Historic Comeback 80 Years After D-Day

https://www.kxan.com/news/texas/inside-battleship-texas-historic-comeback-80-years-after-d-day/

Gulf Copper Enrolls in the Green Marine Program

Galveston Shipyard Environmental Policy and Green Marine Program Participation

Gulf Copper & Manufacturing has enrolled its Galveston shipyard in the Green Marine program. Green Marine is a voluntary environmental certification program for the North American marine industry that provides a roadmap for Gulf Copper to meet its environmental goals. The program evaluates participating shipyards, ship owners, terminals, and port authorities based on established air, land, and water pollution performance indicators.

“Gulf Copper looks forward to participating in the Green Marine program and utilizing the principles and guidance to foster a culture of environmental stewardship,” said Mike Haughton, Gulf Copper ESH Manager. “We’re committed to identifying industry best practices to continually improve our environmental performance now and in the near future.” (more…)